Laminate Pressing and Panel Production

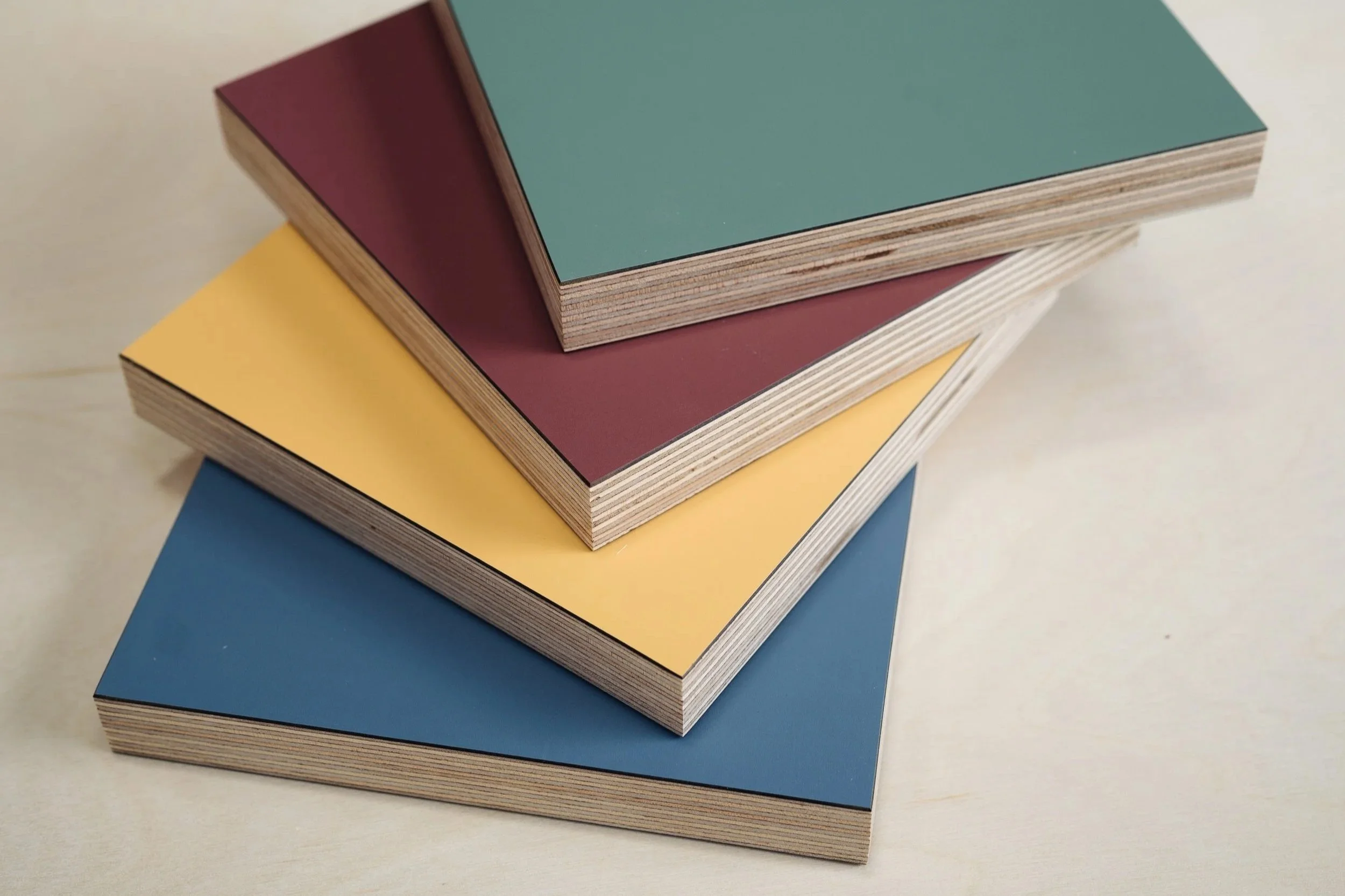

Apply Works provides laminate pressing and bonded panel production for designers, contractors and manufacturers requiring production-ready sheet materials for furniture and interior applications.

We operate a heated hydraulic press capable of pressing panels up to 2500 mm × 1300 mm, with a 300 mm daylight allowing large batches to be processed efficiently in a single operation. The heated platens also enable rapid curing for individual panels, supporting both high-volume runs and fast-turnaround projects.

Materials and Applications

We routinely press a wide range of decorative and technical surface materials, including:

High-pressure laminates (Formica, Fenix, Polyrey)

Furniture Linoleum

Veneers and specialty substrates

Common core materials include birch plywood and MDF, with options to laminate plywood-to-plywood to achieve bespoke thicknesses and structural performance.

Pressed panels are frequently transferred directly to our CNC machining department, enabling a fully integrated workflow from raw sheet material through to precision-cut components.

Integrated Manufacturing Workflow

By combining laminate pressing and CNC machining under one roof, we offer a streamlined production process that:

Shortens lead times

Reduces handling and transport

Improves consistency and quality control

Lowers overall project cost

This integrated approach is particularly suited to commercial furniture, retail environments, cabinetry systems and shopfitting projects where accuracy, repeatability and delivery reliability are critical.

Technical Support and Production Planning

We work collaboratively with clients to advise on:

Material selection

Adhesives and bonding methods

Panel build-ups and thickness tolerances

Production sequencing for machining and assembly

Whether supporting a one-off prototype or a repeatable production run, we provide practical manufacturing input to ensure panels are suitable for downstream processes and site installation.

Enquiries and Technical Briefs

To discuss a laminate pressing project, send us your drawings, material specifications and quantities. We’ll review the requirements and provide a production-led quotation and lead time.

Explore projects here ↴

GET A QUOTE

1. Get in touch and tell us what you need to achieve.

Send us some information about your requirements and project details.

2. Give us some detail - Materials? Quantities?

Specify the core material you require, for example Birch plywood, chipboard or MDF. Provide details of your chosen laminate and whether you require the laminate on both faces (this is often necessary to balance the tension in the core material). If you are unsure on materials specifics, don’t hesitate to get in touch as this is something we are more than happy to advise you on.

We can also laminate multiple boards of standard sheet materials if you require a different material thickness.

3. We'll put together a quote

We'll aim to respond with a quote within 24 hours. Larger jobs will require more time but we'll tell you this.

4. Happy? Then we'll schedule your work in.

Once you're happy to proceed then we'll book your job in. Smaller jobs are usually turned around within 5 days. For larger jobs we'll let you know. If you're in a real hurry then let us know and we'll try our best to help.